What is STM patch processing?

In simple terms, STM patch processing refers to the accurate and precise soldering of various electronic components to PCB boards through instruments, which is one of the most important technologies in modern electronic manufacturing. Since the components are very small, a variety of special machines are needed in the operation process, including solder paste printers, patch machines, reflow soldering, AOI detectors, component cutting machines, wave soldering, tin furnaces, board washers, ICT test fixtures, FCT test fixtures, aging test racks, etc. PCBA processing plants of different sizes are equipped with different production equipment.

STM patch process

The basic process elements of SMT are: solder paste printing--> parts placement--> oven curing--> reflow soldering--> AOI optical inspection--> maintenance--> board cleaning.

Detailed introduction to STM patch process

1. Solder paste printing: The solder paste or patch glue is printed onto the pads of the PCB to prepare for the soldering of components. The equipment used is a (stencil printer), which is located at the forefront of the SMT production line.

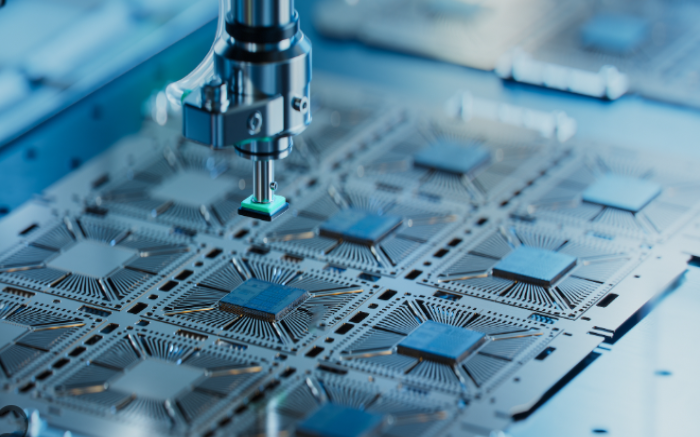

2. Parts placement: Its function is to accurately install the surface mounted components on the fixed position of the PCB. The equipment used is a placement machine, which is located behind the steel screen printer in the SMT production line.

3. Curing in the oven:The furnace carrier can be designed with ribs that just support the position of heavier parts, so that heavier parts are not easy to fall during the second reflow.

4. Reflow soldering: Its function is to melt the solder paste so that the surface mounted components and the PCB board are firmly bonded together. The equipment used is a reflow oven, which is located behind the oven carrier in the SMT production line.

6. AOI optical inspection: Its function is to inspect the welding quality and assembly quality of the assembled PCB board. If necessary, magnifying glasses, microscopes, online test instruments (ICT) and other instruments will also be used.

7. Maintenance:Its function is to rework the PCB board that has been detected to be faulty. The tools used are soldering iron, rework workstation, etc. It can be configured at any position in the production line.

8. Washing the board: Its function is to remove the soldering residues such as flux that are harmful to the human body on the assembled PCB board. The equipment used is a cleaning machine, which can be located in a non-fixed position and can be online or offline.

Hot Display undertakes various SMT patch OEM

Mounting range: Suitable for 0201, 0402, 0603, 0805, 1206 LED lamp beads, diodes, transistors within 40X40mm, QFP, BGA, etc. with pin spacing greater than 0.3mm

We have all relevant placement machines

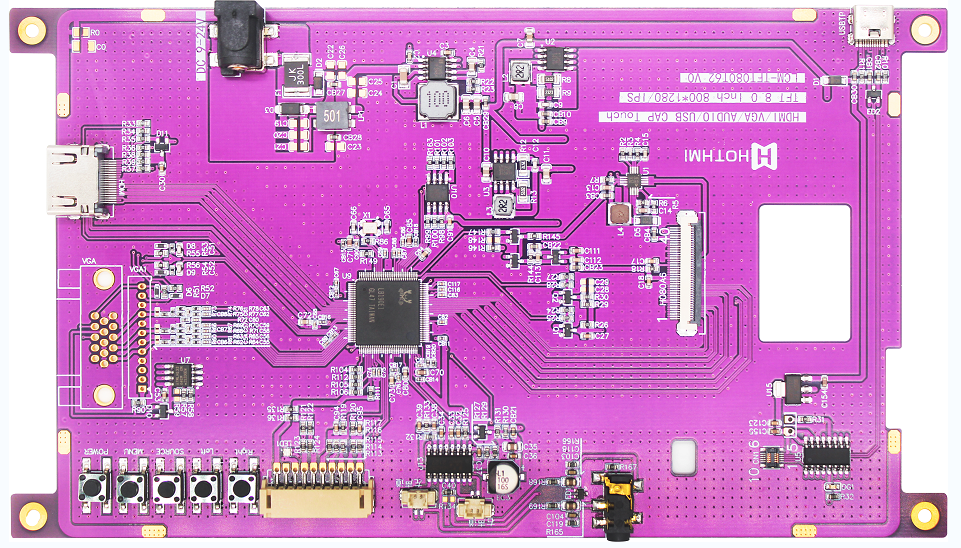

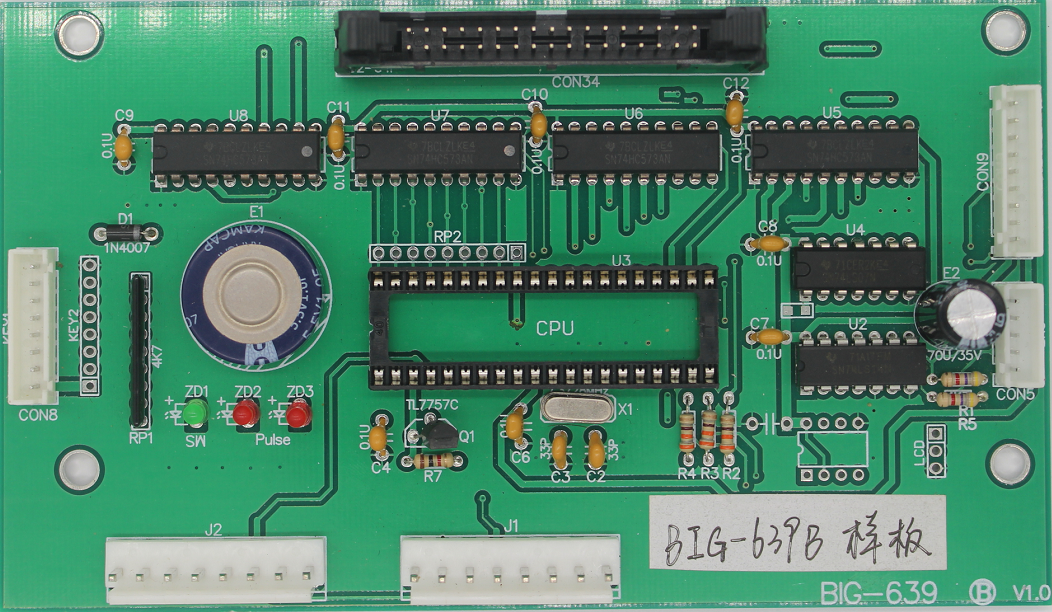

Our finished products

For more services, please contact us!