Many common display screens require backlight to achieve good visual effects. Backlight brightness, uniformity, color, etc. are all influencing factors. Being able to rationalize the backlight design is critical to designing a good display. This article will introduce the components of backlight to provide the optimal solution for each customer.

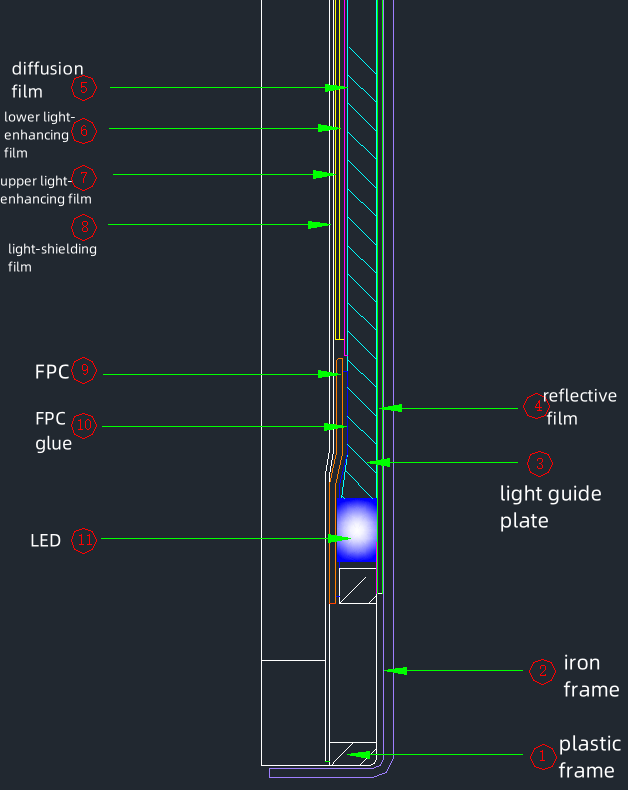

Backlight composition(As shown in the picture below): LED, FPC glue, FPC, light-shielding film, upper light-enhancing film, lower light-enhancing film, diffusion film, reflective film, light guide plate, iron frame, plastic frame

The role of each component of the backlight

1. Plastic frame: The backlight panel has a protective effect, making the entire backlight panel stable and protecting the internal structure of the backlight panel from damage.

2. Iron frame: Made of iron material, it has strong toughness and prevents the backlight panel from being pulled and broken.

3. Light guide plate: The optical grade acrylic plate is used to absorb the light emitted from the lamp and stay on the surface of the optical grade acrylic plate. When the light hits each light guide point, the reflected light will spread to various angles, and then the reflection conditions will be destroyed by the guide plate. The light plate is emitted from the front. The light guide plate can be made to emit light uniformly through various light guide points of different density and size. The purpose of the reflective sheet is to reflect the light exposed on the bottom surface back into the light guide plate to improve the efficiency of light use.

4. Reflective film: Reflect the emitted light source to the corresponding position to make the backlight display uniform.

5. Diffusion film: A key component in the backlight module, which can provide a uniform surface light source for the LCD display. Generally, traditional diffusion films mainly add chemical particles one by one as scattering particles into the diffusion film base material.

6&7. Upper (lower) light-enhancing film: It is a new type of high-performance optical film due to its microscopic prism array structure on the surface. The light-enhancing sheet product is based on a PET substrate. The optical glue is solidified into a pre-designed optical microprism structural coating through a precision coating structural micro-replication method, and the microprism structure is used to converge the light, so that the scattered light is directed towards the PET substrate. It is a new high-performance optical material that concentrates on the front side, thereby improving the overall brightness and uniformity of the LCD panel.

8. Light-shielding film: Prevents beam astigmatism and light leakage, ensuring that each beam is fully utilized.

9. PFC: conductive effect. Has positive and negative levels.

10. FPC glue: Silica gel is generally used, which has a waterproof and corrosion effect on FPC.

11. LED: It is the core of the backlight, and the light source is emitted from here.

For more related knowledge, please contact us!