Capacitive touch screens are widely used because they can provide a good human-machine interface. They not only have smooth operation performance, but also have a long service life. With the continuous advancement of capacitive touch screen technology and the control of costs at a reasonable level, they have gradually replaced resistive touch screens.

The structure of capacitive touch screen

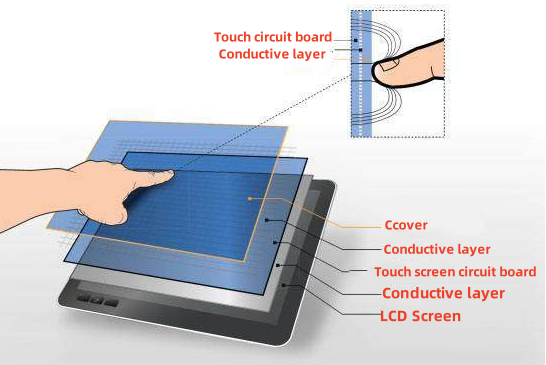

The structural composition of capacitive touch screens mainly includes the following parts, each of which has its specific function and works together to achieve touch detection and response:

1. Protective glass layer: usually made of tempered glass (such as Gorilla Glass). Provides mechanical protection against scratches and breakage while ensuring good optical transparency.

2. Conductive layer (sensing layer): transparent conductive materials such as indium tin oxide (ITO), and sometimes other transparent conductive films are used. Forms a capacitive sensing network that can detect changes in capacitance when touched.

3. Insulating layer: transparent insulating material, such as polyester film or silicon oxide layer. Isolates the conductive layer from the electronic control circuit to prevent short circuits and maintain the electrical characteristics of the touch screen.

4. Substrate layer: usually a glass or plastic substrate. Provides structural support and stability so that the touch screen can be securely mounted on the device.

5. Electrode layer: Electrodes made of conductive materials (such as silver nanowires, copper nanowires, etc.). Forms an electrode grid for capacitive sensing and participates in the formation and detection of capacitance changes.

6. Controller chip: usually located at the edge or back of the touch screen. Responsible for processing the capacitance change signals collected from the conductive layer and the electrode layer, calculating the touch position, and transmitting the data to the device's main processor.

7. Encapsulation layer: Various encapsulation materials, such as adhesives or encapsulation glue. Bonding the various layers of materials together firmly prevents dust and moisture from entering the touch screen, ensuring the durability and reliability of the touch screen.

(Figure 1 Capacitive touch screen structure)

Hierarchical structure

The layers of a capacitive touch screen are usually arranged in the following order:

1. Outermost layer: protective glass layer

2. Conductive layer: ITO or other transparent conductive film

3. Insulating layer: transparent insulating material

4. Electrode layer: conductive electrode

5. Substrate layer: glass or plastic substrate

Through this hierarchical structure, each part can work together to realize the function of capacitive touch screen. When touching, the finger changes the capacitance value between the conductive layer and the electrode layer. After the controller chip detects these changes, it calculates the touch position and converts it into specific touch coordinates, which are then transmitted to the device for response.

This complex structural design enables capacitive touch screens to achieve high sensitivity, multi-touch and high durability, and is widely used in various electronic devices.

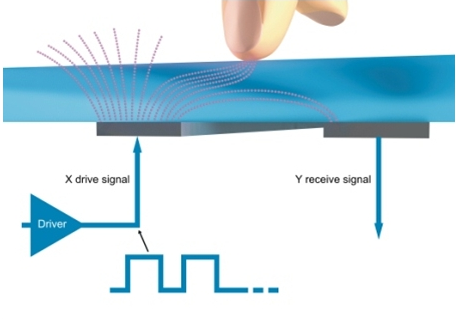

How capacitive touch screens work

Capacitive screens work through any object that holds an electric charge, including human skin. (Charge carried by the human body) Capacitive touch screens are made of materials such as alloys or indium tin oxide (ITO), and the charge is stored in micro-static networks that are thinner than a hair. When a finger touches the screen, a small amount of current is absorbed from the contact point, causing a voltage drop in the corner electrode, and the purpose of touch is achieved by inducing the weak current of the human body. As shown in Figure 2.

(Figure 2: When a touch occurs)

The four corners of the capacitive touch screen are plated with conductive alternating electric fields. The outermost layer is the electrode, which forms a low-voltage high-frequency current on the conductive layer and a 15wm thick transparent iron oxide layer on the working surface as a protective layer. When the user touches the capacitive screen, the user's hand closes the capacitor, and part of the high-frequency current flows from the finger to the human body, destroying the high-frequency current flowing from the four-corner electrodes. The high-frequency current flowing from the four-corner electrodes to the finger is inversely proportional to the distance from the finger contact point to the four-corner electrodes, so the coordinate value of the touch point can be calculated from the ratio of the change in the amount of flow from the four-corner electrodes to the electrodes.

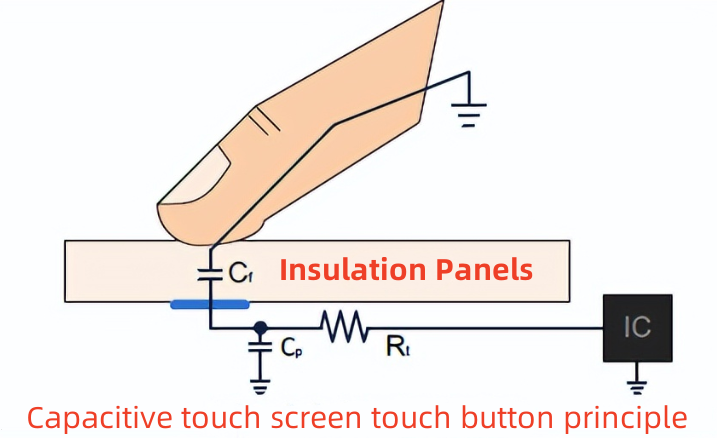

To achieve multi-touch on a capacitive screen, it depends on adding mutual capacitance electrodes. Simply put, the screen is divided into blocks, and a group of mutual capacitance modules are set in each area to work independently, so the capacitive screen can independently detect the touch situation of each area. After processing, multi-touch can be easily achieved. As shown in Figure 3.

(Figure 3: Circuit diagram when a touch occurs)

Recommended articles related to touch screens:

What is the structural composition of a four-wire resistive touch screen?

The working principle of a four-wire resistive touch screen

The detection method of a four-wire resistive touch screen

For more information about capacitive touch screens and product recommendations, please contact us directly!