Electronic paper concept:

At present, flexible electronic paper can be made of plastic, thin metal and ultra-thin glass substrates. The overall structure of flexible electronic paper can generally be divided into two parts: "front plane" and "back plane". The front plane mainly refers to the display medium part of the outer layer of the electronic paper, and the back plane mainly refers to the driving circuit part of the electronic paper.

Electronic paper has a wide range of uses. The first generation of products is used to replace conventional display devices. The second generation of products includes mobile communications and handheld device displays such as PDAs. The next generation of products planned to be developed is positioned in ultra-thin displays, forming application areas related to the printing industry, such as portable e-books, electronic newspapers and IC cards, which can provide reading functions and usage attributes similar to traditional books and periodicals.

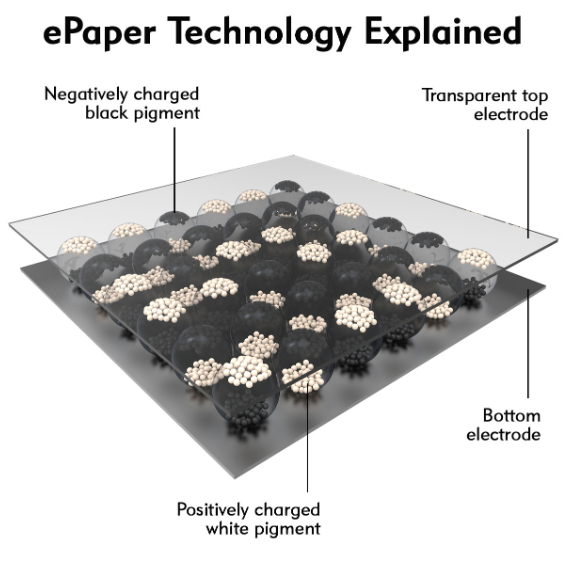

(Schematic diagram of electronic paper structure)

Features of electronic paper

To sum up, electronic paper has the following advantages and disadvantages

1. Advantages

(1) Better reading conditions:

Even if you stare for a long time, your eyes will not feel tired, and you can adjust and process the light perception on the surface.

(2) High contrast:

It relies on ambient reflected light to display. The stronger the ambient light, the higher the contrast. Compared with LCDs that rely on their own light, it is particularly suitable for outdoor viewing. The reflectivity is 6 times that of liquid crystal, and the contrast is 2 times that of liquid crystal and 2 times that of newspapers.

(3) Environmental protection, reducing the use of paper:

If newsprint, student textbooks, teaching aids and documents are replaced by electronic paper, it can not only save printing, distribution and transportation costs, but also eliminate the printing process, achieving the purpose of reducing environmental pollution.

(4) Low power consumption:

Electronic paper has a bistable characteristic and a picture memory function. It does not consume power when the picture does not change, and only consumes power when turning pages.

(5) High resolution:

Mass production products can reach a resolution of 200dpi, and experimental products are even higher.

(6) Thin and light:

No backlight module is required, and the thickness can be very thin and light. The thickness is usually 0.5mm, while LCD is 2mm.

(7) Potential for low cost:

No backlight module is required, no strict packaging is required, and solution processing technology (such as printing) is feasible.

(8) Low investment cost:

Not necessarily a glass substrate, no expensive production line is required.

(9) Flexible substrate:

It can be glass, or the surface of resin, metal, etc.

(10) Wide viewing angle

Due to the microsphere structure, the reflection surface is wide and the viewing angle can reach 180°. LCD requires additional special adjustments to reach more than 80°.

2. Disadvantages

(1) Slow response speed:

The top-level e-paper has a response time of about 50ms, while the mass-produced e-paper has a response time of 200~500ms, while LCD usually has a response time of 15~30ms, which means that e-paper cannot play programs with continuous images.

(2) High difficulty in achieving color:

The display principle of e-paper is black and white particles. To display color, a color filter must be added. Although LCD also needs to use a color filter, the brightness and contrast of e-paper will be greatly reduced after adding a color filter.

(3) Low yield leads to high cost:

The main process is a chemical process that is difficult to control. At present, it still needs to rely on large-scale shipments to explore the experience of improving yield.

(4) Complex driving.

(5) Short lifespan, which is 5~10 years, and is not suitable for long-lasting automotive products.

Current status and development trend of electronic paper technology

1. Current situation

Current Status of E-paper Technology Development In the 1990s, e-book products using liquid crystal display panels appeared in mainland my country, but they were not accepted by people because of the poor display characteristics of liquid crystal display panels like paper. With the development of new liquid crystal materials, it is possible to promote the emergence of a new generation of liquid crystal e-paper.

As for electrophoretic display, its paper-like display performance is well recognized by people and has become the mainstream technology for commercialized electronic paper display products. The research on electrophoretic display panel technology in mainland my country started late, but has made rapid progress. Domestic thin film transistor liquid crystal display manufacturers have also actively invested in the research and development of TET active electrophoretic display electronic paper panel technology. E-book products using electrophoretic display electronic paper display panels appeared in mainland China in 2006, and the market scale has expanded rapidly.

2. Development trend of electronic paper technology

Browsing "electronic publications" has become a fashionable way of reading and is gradually accepted by people. People hope to develop a portable display with low energy consumption, high reflection, wide viewing angle, ultra-thin and light weight. The emergence of electronic paper display technology (E-Paper technology) has made this hope a reality and has opened up the application space of flat panel display technology in the field of media products.

At present, the mainstream product of electronic paper is electrophoretic display electronic paper. The main supplier is E-Ink, a subsidiary of Taiwan's E Ink Technology (E-Ink International Holdings Co., Ltd.). Since its market share accounts for more than 95%, it is in a monopoly position and has mastered the market pricing power. In recent years, the price of display screens using electronic paper has also dropped, but the magnitude is not large, and the motivation for price reduction is mainly to expand the market and compete with iPad, rather than competition among peers.

Since nano electronic ink display technology is still in the early stage of commercialization of color display, the current main task is to improve color display technology as soon as possible and develop the market. Its technical development trends can be summarized as follows.

(1) Development from static display to dynamic display. Most of the electronic papers currently developed can only display monochrome static images. Developing products that can realize color display and dynamic images is an inevitable trend in the development of electronic paper. The response time of existing products is 150~200ms, which is much slower than the 5ms of LCD displays. In order to improve the dynamic display effect of electronic paper, it is imperative to improve its response time.

(2) The development of dual-color display to color display. The realization of color display through layered color filters is one of the ways to achieve colorization of electronic paper.

(3) The development of rigid display to flexible display. Vigorously develop a-Si TFT technology suitable for low-temperature process. Oxide semiconductor TFT and organic TFT are the direction of low-temperature process TFT, which can be used as a breakthrough for flexible substrate electronic paper.

(4) The development of high cost to low production cost. The main aspect of low-cost production is to develop and adopt roll-to-roll process technology. This process is completely different from the traditional flat panel display process. The process is simple, efficient, and the equipment is cheap. It can greatly reduce the production cost and is the ultimate goal of electronic paper production.

Nothing is more important than reliability at a low price! Hot Display is an expert in display manufacturing with a complete range of products and excellent quality! We provide a variety of display solutions, tailor-made for you.

Welcome to contact us!